Guaranteed energy supply and a reduction in carbon emissions by 1890 tonnes per annum

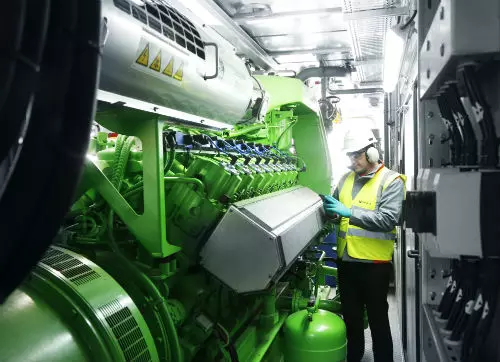

Veolia UK is boosting Cranswick Foods’ sustainability by delivering energy to their production lines using Combined Heat and Power, CHP, technology. One of the UK’s largest food manufacturers, Cranswick Foods will now be able to guarantee the energy needs of the production facilities at the Milton Keynes site and reduce carbon emissions by 1890 tonnes per annum. To support the Cranswick Group’s target of reducing their carbon footprint by 30% by 2020 against its 2010 baseline, Veolia have designed and installed a 1189kWe CHP unit and waste heat boiler to provide low carbon electricity, hot water and steam to the production lines. Targeting all aspects of environmental sustainability, Cranswick's dedication to the reduction of its carbon footprint is key to their business strategy and energy plays a vital role in the processing operations covering a product range spanning meat, poultry, bacon, antipasti, pâté, cheeses, pizza toppings and fresh pasta.

The CHP delivers around 10GWh of electricity each year which will take pressure off the local electricity infrastructure. As well as reducing carbon emissions, the £1.245bn food business will also benefit from stable energy costs that are less susceptible to energy market price changes and the CHP technology will back the company’s drive to implement the ISO 14001 Environmental Management standard.

Commenting on this latest CHP application for the food industry, Damian Shevloff, Managing Director of Veolia CHP UK said, “We look forward to helping Cranswick Foods achieve their carbon savings target and supporting their commitment to the environment. As the UK struggles to generate sufficient energy to supply both its industrial, commercial and domestic customers CHP can play a key role in guaranteeing sustainable electricity and heat for industry. With over 80MWe already operational Veolia CHP systems annually save over 158,000 tonnes of CO2 emissions for UK industry and make a real difference in delivering the energy needed to maintain modern production facilities.“

The contract scope includes a fully engineered package covering installation of the CHP, a 690kg/hr waste heat steam boiler, flue, heat exchangers, pipework, cabling and ancillary equipment. The Veolia CHP is one of the new lean burn units that deliver the high electrical efficiency required to support this type of production process. Also included in the contract is a 10 year operation and maintenance service, provided by Veolia’s nationwide service teams and this will guarantee availability on a 24/7 basis.

By harnessing the heat produced in the generating process and reducing transmission over long distances by being site based, the CHPs save energy and carbon emissions. This makes them typically twice as energy efficient as grid supplied electricity and separate heat plant.